IGE-Hydrofarm Commercial Product Categories

Controlled Environment Ag (CEA) Industries We Serve

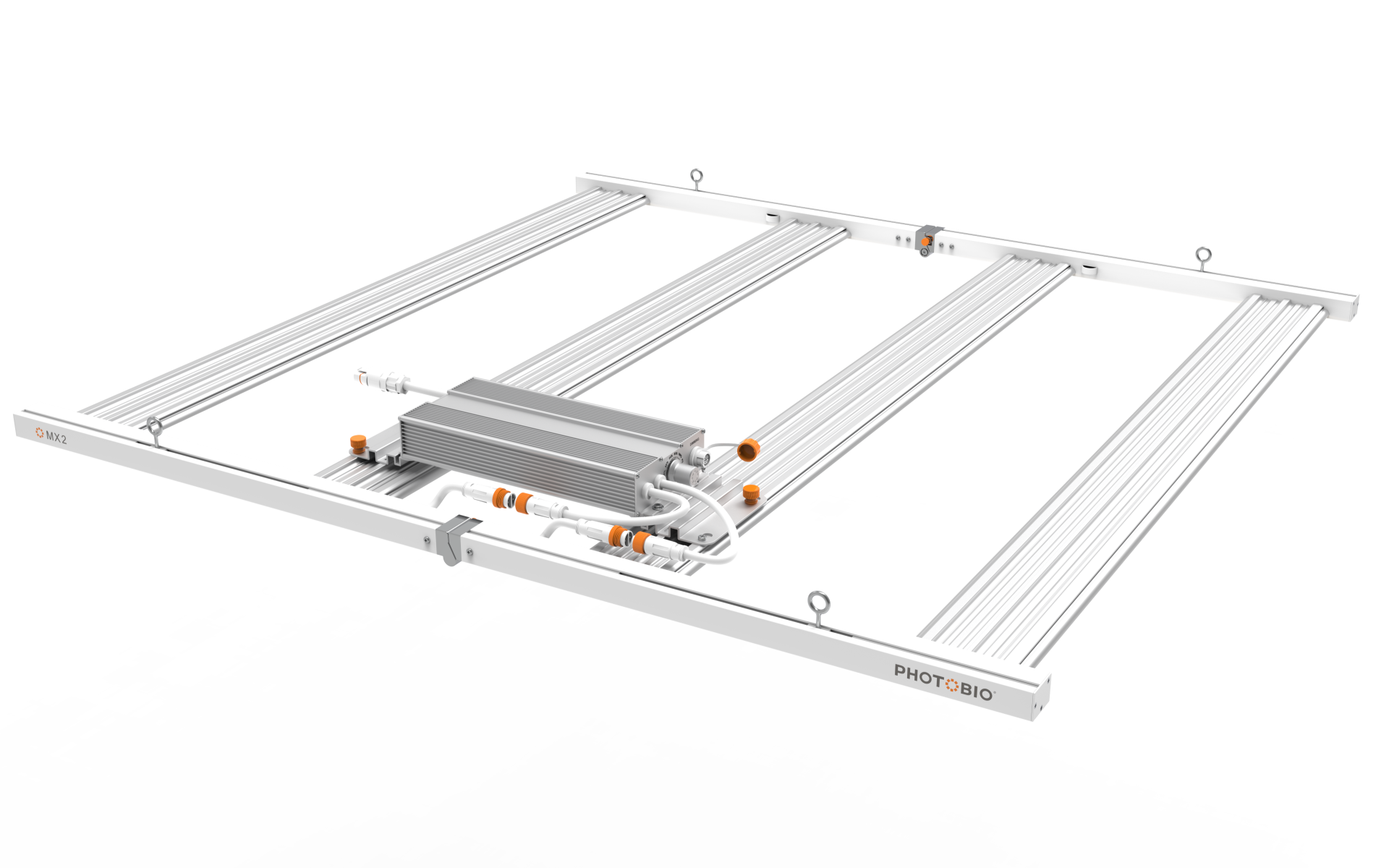

Featured Product

The PHOTOBIO•MX2 is going to change everything!

We’ve crafted a fixture that not only surpasses its predecessor but also maintains the trusted spectrum essential for your crops.

- 1,870 uMol/s (PAR), achieving an unmatched efficacy of 2.8 uMol/J.

- 10% boost in both photon output and efficiency while cutting down the weight by nearly half.

Higher yields and lower costs with PHOTOBIO MX2.

We Stand Behind Our Products

At IGE-Hydrofarm Commercial, we stand behind all our commercial cannabis grow equipment and services that we manufacture, sell, and install for our customers. We follow strict quality control guidelines.

American-Made

The design and manufacturing of all Innovative Growers Equipment systems are handled in our US manufacturing facility to keep our quality standards at the highest level. Our products are designed and built under exacting standards to ensure quality American Made Products for our customers.

Customer Satisfaction

If there is a quality control concern upon receiving your products, we will work hard to make sure it is resolved in a timely manner and to our customers’ satisfaction.

Custom Design &

Installation Services

Scheduled

Fulfillment